Meticulous selection for top grade quality.

PRODUCTS

CONTACT

- Phone: +86-15195663876

- Email: [email protected]

- Address: No.8, Police Road, Dongqiao, Huangdai, Xiangcheng District, Suzhou, China

-

Anti- Static/ ESD PC Sheet/ Board Polycarbonate solid sheet

-

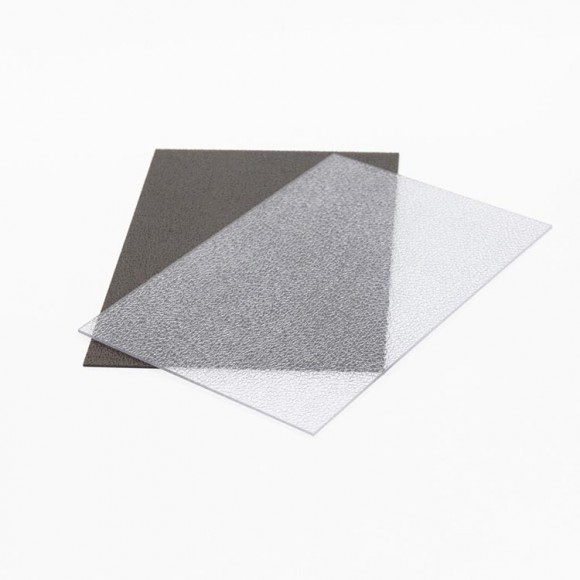

Particle Polycarbonate sheet 100% Virgin Embossed PC Sheet

-

Frosted Polycarbonate solid sheet

-

Hardened solid PC Sheet / Board Polycarbonate solid sheet

-

Polycarbonate solid sheet Frame Retandant fire resistance PC sheet board

-

Bullet Proof Polycarbonate solid Sheet PC board

Polycarbonate Solid Sheet is a good substitute for glass, its weight is half that of a glass of the same thickness, and its impact resistance is 30 times that of ordinary tempered glass High-security insurance and excellence sunlight effect, low weight, easy to install, and various colors can also meet the appearance requirements of different buildings. Polycarbonate solid sheet refers to a type of durable and transparent material made from polycarbonate resin. It is commonly used in construction, manufacturing, and various applications where strength, transparency, and resistance to impact are important. These sheets are also highly resistant to weathering, including ultraviolet (UV) radiation. This makes them suitable for outdoor applications such as skylights, greenhouses, and protective coverings.

-

Introduction to Solid Polycarbonate Sheets Solid polycarbonate sheets are a versatile thermoplastic material widely used in construction, in...

READ MORE -

Introduction to Corrugated Polycarbonate Sheets Corrugated polycarbonate sheets are durable, lightweight plastic panels used extensively in ...

READ MORE -

Understanding Solid Polycarbonate Sheets in Modern Construction Solid polycarbonate sheets are high-performance thermoplastic panels widely ...

READ MORE -

Understanding Acrylic Sheet and Its Benefits Acrylic sheet, commonly known as Plexiglass or PMMA, is a versatile thermoplastic material that...

READ MORE

What is the impact resistance of polycarbonate solid sheet?

Polycarbonate solid sheet have excellent impact resistance and are generally more durable than traditional materials such as glass. Its impact resistance is mainly due to its special material properties and structural design.

Polycarbonate solid sheet are made of polycarbonate resin, a material with high strength and toughness. Compared with fragile materials such as glass, polycarbonate has better bending strength and impact energy absorption capabilities.

Solid polycarbonate sheet typically feature single- or multi-layer structural designs, which include one or more layers of polycarbonate sheets bonded to each other. This design helps absorb and disperse impact, reducing the risk of chipping.

Due to the high impact strength of polycarbonate solid sheets, they are often used as a replacement for glass, especially in high-risk environments such as stadiums, greenhouses, stations, etc. against storms, vandalism, or accidental collisions. Bus shelters, etc.

Due to its high impact resistance, solid polycarbonate sheet are less susceptible to cracking or chipping and therefore have a longer service life, reducing the frequency of maintenance and replacement while also reducing safety risks.

What should you do if your polycarbonate solid sheet is damaged or cracked?

If a polycarbonate solid sheet is damaged or cracked, appropriate measures should be taken to repair or replace it, depending on the situation. Here are some common ways to deal with it:

For minor damage or cracks, try using clear polycarbonate glue to repair them. First, clean and dry the damaged area, then apply clear glue to the crack and use pressure to flatten it. After the glue has dried, the necessary sanding and polishing can be done to restore the smoothness and transparency of the surface.

If the damage is more severe, such as extensive cracking or chipping, it may be necessary to replace the damaged section or the entire solid polycarbonate sheet. Before replacement, be sure to completely remove the damaged parts to ensure that the new material is installed smoothly and securely.

It is important to pay attention to safety when handling damaged solid polycarbonate sheet. If the damaged area is sharp or has edges, take appropriate protective measures to avoid accidental scratches or injuries.

For large or complex damage, it is best to have it repaired or replaced by a professional. They have the experience and skills to ensure the quality and safety of the restoration work.