Meticulous selection for top grade quality.

PRODUCTS

CONTACT

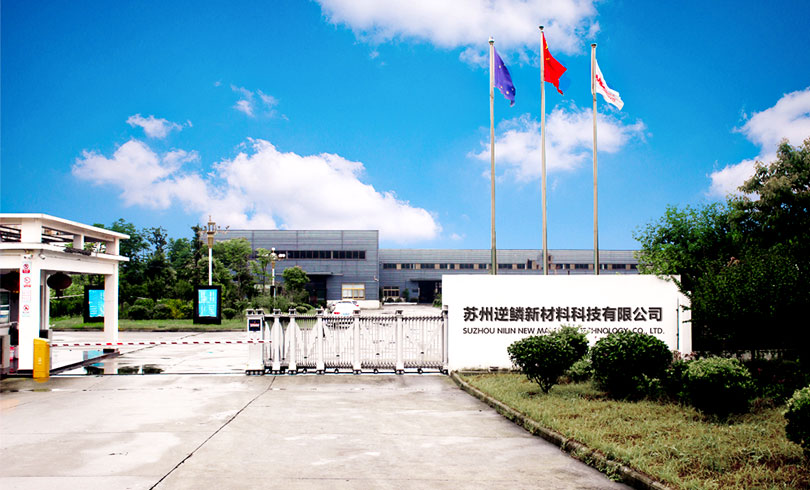

- Phone: +86-15195663876

- Email: [email protected]

- Address: No.8, Police Road, Dongqiao, Huangdai, Xiangcheng District, Suzhou, China

-

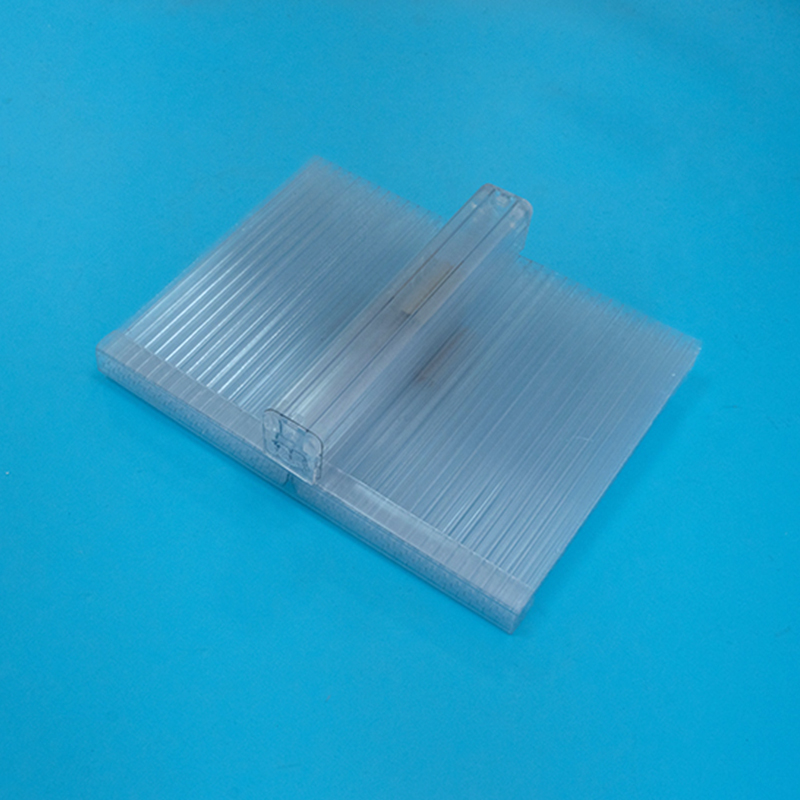

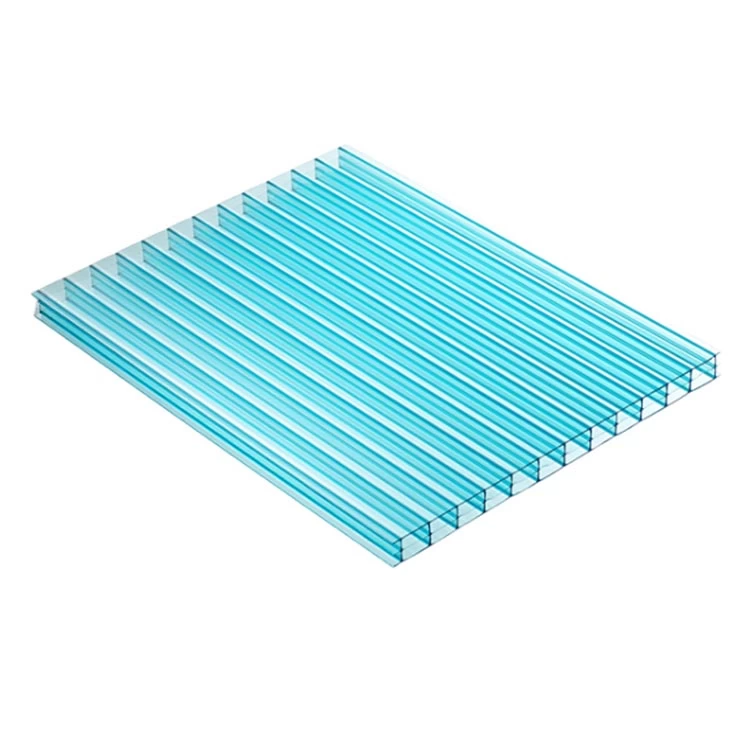

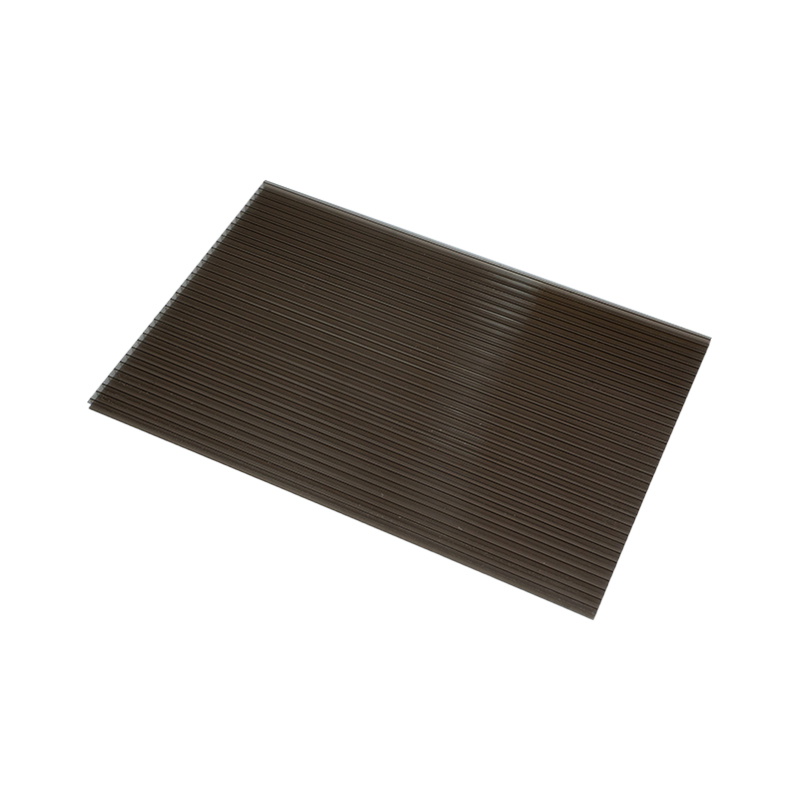

Tinted Plastic Plug-inpattern PC Hollow Sheet

-

Outdoor Partition U Lock Interlocking Hollow Polycarbonate Sheet

-

4x8 Sheet PC Plastic Honeycomb Sandwich Hollow Sheet

-

Triple Wall Hollow Polycarbonate Alveolar PC Hollow Sheet

-

Robust Durable Storage Container Partition Polycarbonate Hollow Sheet

-

Clear X Structure 5-Wall Hollow Polycarbonate Sheet

Polycarbonate Hollow Sheet is a reinforced board that add oblique support to the rectangular section of ordinary hollow boards to improve the overall bearing capacity of the board. The board can support larger purlin spacing and mini mizethe profile The amount of usage allows designers to have more room to play when selecting materials. The increased oblique support of the board plays a positive role in the lateral stability of the hollow board, making the overall structure of the board more reasonable. Low U value can meet the appearance requirements of different buildings. Similar to solid sheets, polycarbonate hollow sheets are lightweight, making them easy to handle and install. The hollow structure reduces the amount of material used while maintaining strength and rigidity.

-

Introduction to Solid Polycarbonate Sheets Solid polycarbonate sheets are a versatile thermoplastic material widely used in construction, in...

READ MORE -

Introduction to Corrugated Polycarbonate Sheets Corrugated polycarbonate sheets are durable, lightweight plastic panels used extensively in ...

READ MORE -

Understanding Solid Polycarbonate Sheets in Modern Construction Solid polycarbonate sheets are high-performance thermoplastic panels widely ...

READ MORE -

Understanding Acrylic Sheet and Its Benefits Acrylic sheet, commonly known as Plexiglass or PMMA, is a versatile thermoplastic material that...

READ MORE

Will temperature changes affect the durability of polycarbonate hollow sheet?

Temperature changes do affect the durability of polycarbonate (PC) hollow sheet. The following are the possible effects of temperature changes on the durability of PC hollow sheet:

Polycarbonate materials expand as temperatures increase and contract as temperatures decrease. If the temperature changes too drastically or frequently, it may cause internal stress in the material, which may cause fatigue in the long term and affect its durability.

Although polycarbonate has good low-temperature properties, its impact resistance will decrease at extremely low temperatures, making it more brittle and prone to rupture.

Above the long-term service temperature limit of polycarbonate (usually 120°C), the material may soften and deform, affecting its structural integrity.

When exposed to high temperatures for a long time, polycarbonate may undergo accelerated aging, resulting in a decline in material performance.

If there is a large temperature difference on both sides or different parts of the polycarbonate hollow sheet, temperature difference stress may occur, which may cause the material to crack or be damaged.

When designing polycarbonate hollow sheet, the temperature range of the environment in which they are used is usually considered to ensure optimal performance within this range.

What is the durability of polycarbonate hollow sheet under different temperature conditions?

Polycarbonate (PC) hollow sheet is an engineering plastic with excellent performance. Its durability performance under different temperature conditions is as follows:

PC hollow sheet has good low temperature resistance and can usually maintain its physical properties unchanged in the temperature range of -40°C to -100°C, which makes it suitable for cold environments.

The long-term use temperature limit of PC hollow sheet is usually around 120°C, which means that below this temperature, PC hollow sheet can maintain their mechanical properties and chemical stability.

PC materials may undergo thermal degradation at high temperatures, but under normal use conditions, their thermal stability can be improved by adding thermal stabilizers, thereby resisting the effects of high temperatures to a certain extent.

PC hollow sheet will thermally expand as the temperature increases, but this expansion is usually within a controllable range and will not affect the structural integrity of the material.

PC hollow sheet can adapt to temperature difference changes within a certain range, but extreme temperature difference changes may cause thermal stress in the material, leading to performance degradation.

When PC hollow sheet are used outdoors, they will be affected by factors such as ultraviolet rays, temperature changes, and humidity, which may accelerate the aging of the material. Therefore, UV stabilizers and antioxidants are usually added to PC hollow sheet to improve their weather resistance.

PC hollow sheet maintains high impact resistance even at low temperatures, which makes it very popular in applications that require impact protection.