Meticulous selection for top grade quality.

PRODUCTS

CONTACT

- Phone: +86-15195663876

- Email: [email protected]

- Address: No.8, Police Road, Dongqiao, Huangdai, Xiangcheng District, Suzhou, China

-

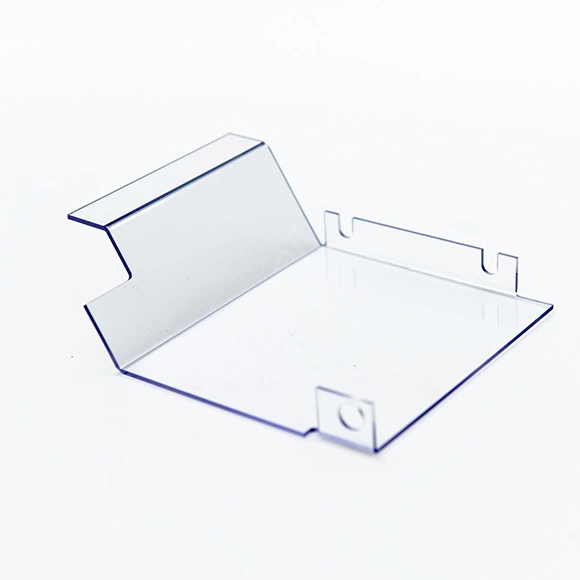

Self-designed Bending Processed Polycarbonate/acrylic Sheets

-

Effective Isolation Mask Processed Items Polycarbonate Acrylic Sheet

-

Thermoformed Expanded Processed Items PC Acrylic Sheet

-

Polycarbonate Sheet Police Riot Shield Processed Items

-

Self-designed Cutting Bending Processed Polycarbonate/acrylic Processed Items

-

Polycarbonate Acrylic Sheet Machinery Equipment Mask Processed Items

-

Introduction to Solid Polycarbonate Sheets Solid polycarbonate sheets are a versatile thermoplastic material widely used in construction, in...

READ MORE -

Introduction to Corrugated Polycarbonate Sheets Corrugated polycarbonate sheets are durable, lightweight plastic panels used extensively in ...

READ MORE -

Understanding Solid Polycarbonate Sheets in Modern Construction Solid polycarbonate sheets are high-performance thermoplastic panels widely ...

READ MORE -

Understanding Acrylic Sheet and Its Benefits Acrylic sheet, commonly known as Plexiglass or PMMA, is a versatile thermoplastic material that...

READ MORE

Can polycarbonate sheets processed to meet a specific design?

Polycarbonate sheets can be processed to meet specific design requirements. Polycarbonate is a versatile thermoplastic material known for its strength, transparency, and flexibility. Here are some common methods for processing polycarbonate sheets to achieve specific designs:

Polycarbonate sheets can be easily cut to desired shapes and sizes using various tools such as saws, routers, or laser cutters. This allows for precise customization according to specific design requirements.

Holes, patterns, and intricate designs can be created on polycarbonate sheets through drilling and milling processes. CNC (Computer Numerical Control) machines can be used for precise and complex designs.

Polycarbonate sheets can be heated and bent into curved shapes or formed into specific contours using techniques such as heat bending or vacuum forming. This enables the creation of custom shapes and designs for applications like architectural glazing or signage.

Polycarbonate sheets can be embossed or textured to enhance their aesthetic appeal or improve functionality. Embossing adds depth and visual interest, while texturing can provide grip or diffused light transmission for applications such as skylights or privacy screens.

Polycarbonate sheets can be printed with graphics, patterns, or coatings to achieve desired visual effects or functional properties. UV-resistant coatings can be applied to enhance weatherability, while digital printing allows for high-resolution images or branding to be directly applied onto the surface.

Multiple polycarbonate sheets can be joined together using adhesives, mechanical fasteners, or solvent welding techniques to create larger structures or assemblies. This facilitates the construction of complex designs such as greenhouse panels or protective enclosures.

Surface treatments such as anti-reflective coatings, scratch-resistant coatings, or self-cleaning coatings can be applied to polycarbonate sheets to improve durability, optical clarity, and ease of maintenance.

The versatility of polycarbonate sheets makes them highly suitable for a wide range of design applications, from architectural glazing and automotive components to consumer electronics and signage. With the right processing techniques, polycarbonate sheets can be tailored to meet specific design requirements in terms of shape, appearance, functionality, and performance.

Can polycarbonate/acrylic sheet processing meet different functional requirements?

Polycarbonate/acrylic sheet processing can meet different functional requirements, depending on the desired application scenario and design needs. The following are examples of some common functional requirements that machining processes can meet:

The strength and durability of the plate can be enhanced by selecting appropriate materials and processing methods during the processing process, making it suitable for applications that need to withstand certain loads or environmental pressures, such as building structures, vehicle components, etc.

For transparent or translucent plates, the processing process can ensure that the surface is smooth and flat without bubbles or defects to maintain good light transmittance and is suitable for lighting, display, decoration and other fields.

By adding special UV protection coatings or materials during processing, the weather resistance and anti-aging capabilities of the board can be enhanced, making it suitable for outdoor applications such as awnings, doors and windows, etc.

Fire retardant materials or fire retardant agents can be used during processing to improve the flame retardant properties of the board and make it comply with fire protection requirements in construction, transportation and other fields.

For applications that require resistance to chemicals or corrosive environments, corrosion-resistant materials or special surface treatments can be selected during processing to enhance the corrosion resistance of the sheet.

By adding conductive or insulating materials during processing, the board can be given specific conductivity or insulation properties, suitable for applications in electronics, communications and other fields.