Building a Durable and Bright Patio Cover or Carport

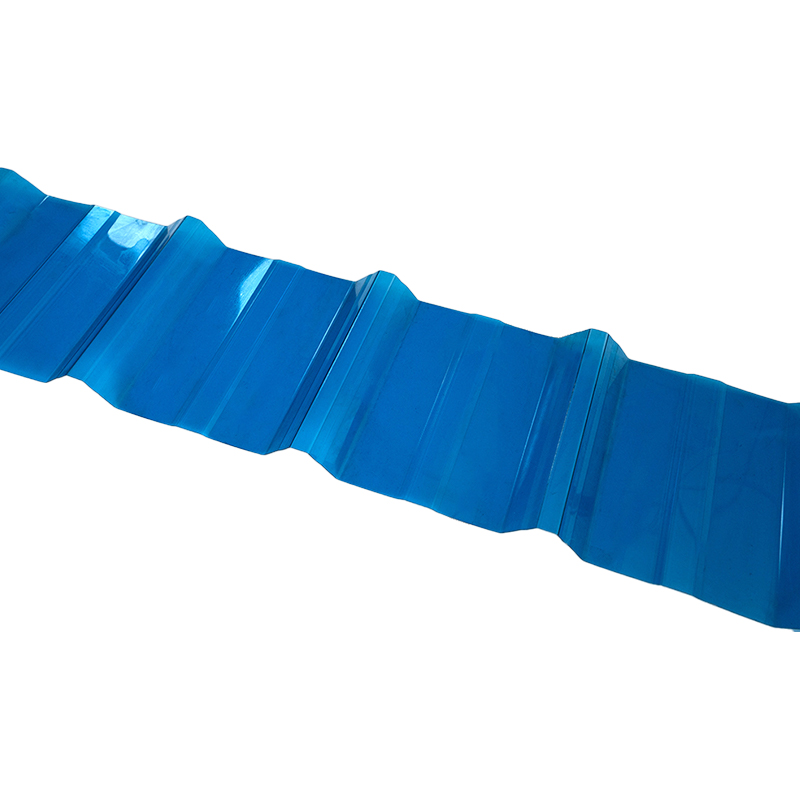

Corrugated polycarbonate sheets have emerged as a premier material for constructing patio covers and carports, offering a compelling blend of durability, light transmission, and design flexibility. Unlike traditional materials such as wood, metal, or fiberglass, these multi-walled plastic panels provide a modern solution that withstands the elements while creating a comfortable, naturally lit space. Their impact resistance far surpasses that of glass, and they are significantly lighter than metal roofing, making installation more manageable. For homeowners seeking to build a structure that protects vehicles or creates an inviting outdoor living area, corrugated polycarbonate presents a practical and long-lasting option that balances functionality with aesthetic appeal.

Key Advantages for Outdoor Structures

Choosing corrugated polycarbonate for your patio or carport brings several distinct benefits that directly address the needs of these applications.

Superior Strength and Weather Resistance

The corrugated profile provides inherent structural rigidity, allowing the sheets to span purlins and withstand significant loads. These sheets are engineered to resist:

- Impact: They are virtually unbreakable, offering excellent protection against hailstones, falling branches, and accidental impacts that could shatter glass or dent metal.

- UV Degradation: High-quality sheets come with a co-extruded UV-resistant layer on the outer surface. This layer prevents yellowing, clouding, and embrittlement for a decade or more, ensuring long-term clarity and strength.

- Extreme Temperatures: Polycarbonate performs well in both scorching heat and freezing cold, maintaining its properties without becoming brittle or warping excessively.

Perfect Light Transmission and Heat Management

This is where polycarbonate excels for creating pleasant spaces. The sheets diffuse sunlight, eliminating harsh shadows and glare while bathing the area below in soft, natural light. You can select from a range of light transmission levels and tints (like bronze or opal) to control brightness and heat gain. A comparison of light properties:

| Sheet Type | Light Transmission | Best For |

| Clear | Up to 90% | Maximum brightness, greenhouses |

| Opal / Milky | 50-70% | Soft diffused light, patio covers |

| Bronze / Grey Tint | 30-50% | Reducing glare & heat, carports |

Critical Installation Considerations

Proper installation is paramount to prevent leaks, noise, and structural stress. Following manufacturer guidelines specific to the sheet profile is essential.

Framework and Support Spacing

The underlying frame (typically aluminum or treated wood) must be sturdy and level. The maximum allowable support spacing (rafter/purlin spacing) depends on sheet thickness, local snow loads, and wind loads. A general guideline is:

- 0.7mm to 1.0mm thickness: Supports every 24 to 30 inches.

- 1.2mm thickness and above: Supports every 36 to 48 inches for standard applications. Always consult local building codes for required loads.

Fastening and Sealing

Use only corrosion-resistant fasteners (stainless steel or aluminum screws with EPDM or neoprene sealing washers). Never drive screws tight against the polycarbonate.

- Drill Oversized Holes: Pre-drill holes 1/8" larger than the screw shaft to allow for thermal expansion and contraction.

- Fasten at the Crest: Always place screws at the top of the corrugation (the ridge), never in the valley, to ensure proper water runoff.

- UV Side Out: Ensure the side marked with the UV-protective coating faces outward, toward the sun.

Managing Expansion, Condensation, and Runoff

Polycarbonate expands and contracts with temperature changes. Account for this by allowing a slight overhang (about 3 inches) and not butting sheets tightly end-to-end. While the sheets themselves are waterproof, proper overlap (typically 1.5 corrugations for side laps and 6-8 inches for end laps) and the use of compatible ridge/edge closure strips are crucial for a weather-tight seal. The corrugated channels will naturally direct water, but the structure should have a minimum pitch of 1/4 inch per foot for adequate drainage.

Practical Limitations and Solutions

While excellent, the material has specific limitations to plan for.

- Scratching: The surface can be scratched during cleaning or by abrasion. Use soft cloths or sponges and mild soapy water for cleaning. Avoid abrasive cleaners or pressure washers.

- Noise Amplification: Rain can be noisier on polycarbonate than on tile or metal. Using thicker sheets and ensuring they are securely fastened to a solid frame can dampen sound.

- Heat Buildup: In very hot climates, a tinted sheet is advisable. For added comfort, ensure the patio cover or carport has ample ventilation at the eaves or ridge to allow hot air to escape.

- Code Compliance: Always check with your local building department. Some municipalities have specific requirements for fire ratings, load calculations, or permits for covered structures.

Making the Right Choice for Your Project

For a successful patio cover or carport, select sheets specifically rated for roofing applications with a guaranteed UV layer. Opt for a tint that suits your climate and desired ambiance. Partner the sheets with a high-quality, properly designed support framework—this is not an area to cut corners. When installed correctly, a corrugated polycarbonate structure provides a brilliant, robust, and maintenance-friendly solution that enhances your home's functionality and value for many years, beautifully merging indoor comfort with the outdoor environment.