Meticulous selection for top grade quality.

PRODUCTS

CONTACT

- Phone: +86-15195663876

- Email: [email protected]

- Address: No.8, Police Road, Dongqiao, Huangdai, Xiangcheng District, Suzhou, China

-

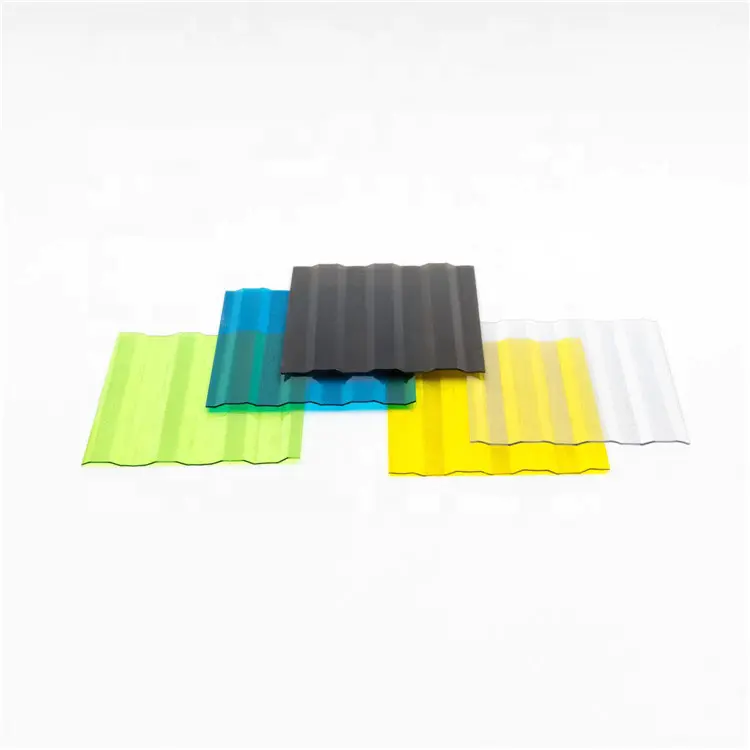

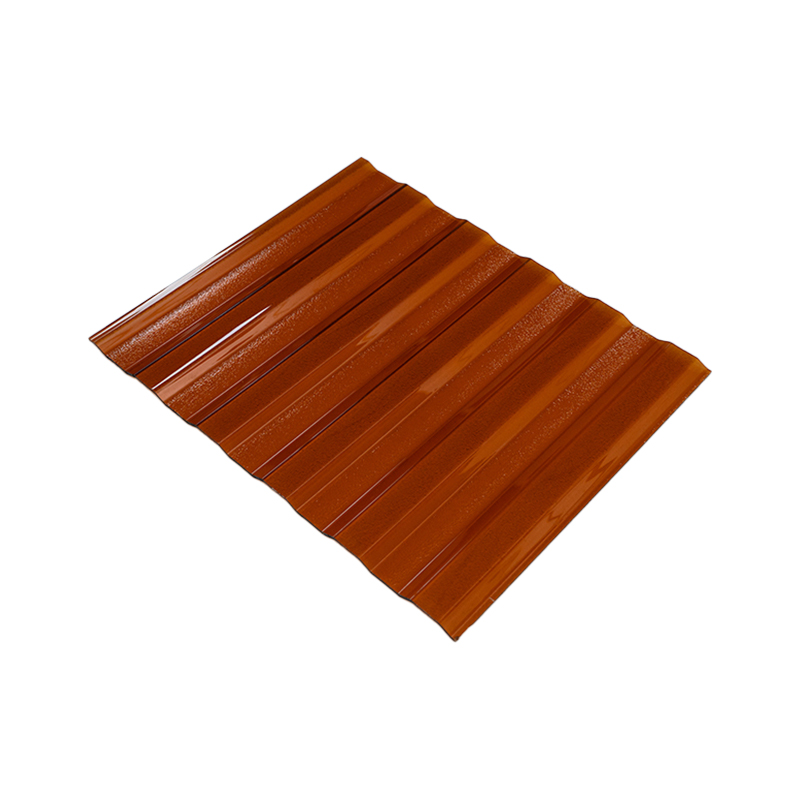

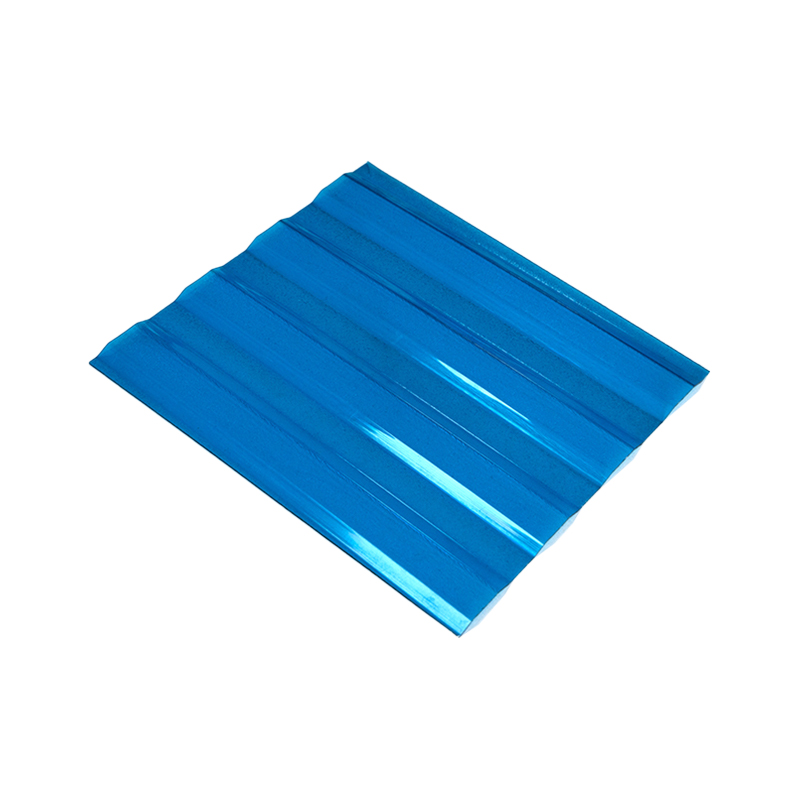

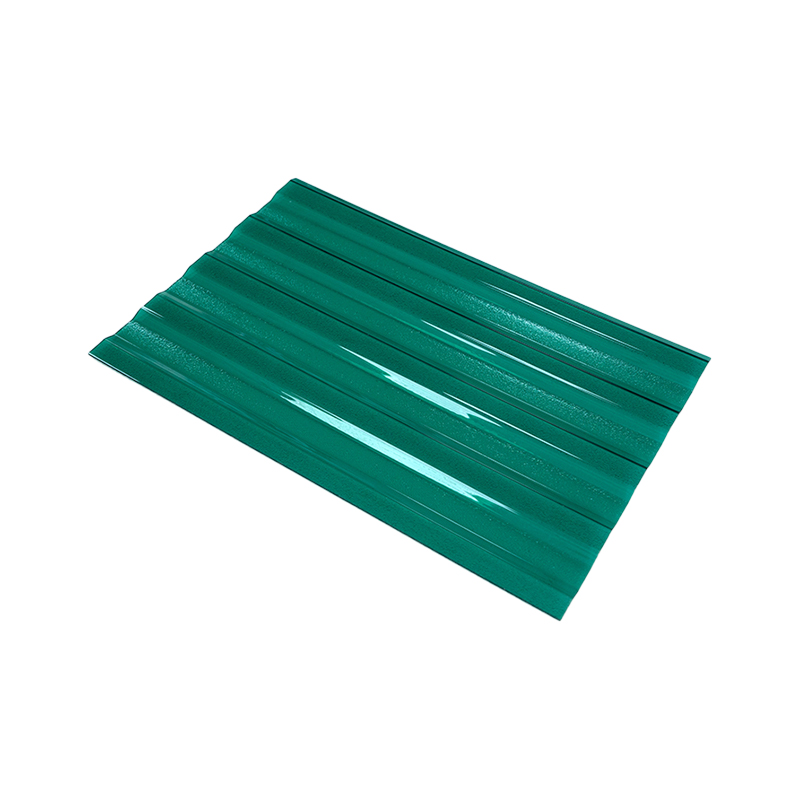

UV Coated embossed & corrugated polycarbonate sheet

-

Anti-Static Function Polycarbonate Embossed Corrugated Sheet

-

10 Years Guarantee Polycarbonate Embossed Corrugated Rolls

-

High Fire Rating For Agriculture And Construction Polycarbonate Embossed And Corrugated Sheet

-

Bayer Material Polycarbonate Embossed And Corrugateds Sheet

-

Double Side UV Beautiful Colors Polycarbonate Embossed And Corrugated Sheet

Polycarbonate Embossed And Corrugated Sheet Use reverse- -static tiny embossed patterns in intervals on both sides of the polycarbonate sheet with corrugate, designed to enhance the tenacity and anti-static function of the sheet. The combination of the embossed and smooth surface has aspecial effect. the rays through the embossed surface directly when it's the strongest in the daytime, the light transmission is 50%, it makes the Sunshine soft. the rays slanted through the smooth surface when it's weak, the light transmission is 90%. it makes the who daytime have soft light.

Product Features

■Less framework than other products, reduce expenses

■Well straight character, 1. 2mm thickness pc Embossed And corrugated Sheet

have the same straight character with 3mm pc soled sheet

■The edge can be overlapped during construction, no water leakage

■Patented structure. nice appearance

■Double slit lighting, soft light transmission

■Has unique anti-static treatment capabilities

-

PVC sheets are versatile plastic materials widely used in construction, interior design, signage, and furniture manufacturing. Known for the...

READ MORE -

Introduction to Solid Polycarbonate Sheets Solid polycarbonate sheets are a versatile thermoplastic material widely used in construction, in...

READ MORE -

Introduction to Corrugated Polycarbonate Sheets Corrugated polycarbonate sheets are durable, lightweight plastic panels used extensively in ...

READ MORE -

Understanding Solid Polycarbonate Sheets in Modern Construction Solid polycarbonate sheets are high-performance thermoplastic panels widely ...

READ MORE

What are the advantages of using anti-static micro-embossed patterns on polycarbonate embossed and corrugated sheets?

Polycarbonate and embossed corrugated sheets have a variety of advantages using antistatic micro-embossed patterns spaced on both sides, including:

The antistatic micro-embossed pattern can effectively enhance the antistatic ability of the corrugated board. This design can reduce or prevent the generation or accumulation of static electricity, reducing the electrostatic charge on the surface of the corrugated plate, thereby reducing dust collection, preventing electrostatic discharge and other problems.

The tiny embossed pattern creates a subtle texture on the surface, which not only increases the aesthetics of the corrugated sheet, but also enhances the tactile feel. This texture makes the corrugated board more textured and increases its visual appeal.

The embossed pattern increases the structural strength of the corrugated board to a certain extent. Tiny protrusions and depressions can increase the surface area of the board, thereby improving the board's bending and compression resistance and increasing the mechanical stability of the corrugated sheet.

Anti-static micro-embossed patterns produce special effects on the reflection and refraction of light. Under different light conditions, such as strong and weak light, this design can provide different light effects, such as softening sunlight and giving soft light during the day.

The embossed pattern forms interesting patterns and textures on the surface of the polycarbonate embossed and corrugated sheets, which increases the beauty and decoration of the corrugated board. This design allows polycarbonate embossed and corrugated sheets to have more application possibilities in construction and decoration, and can meet the aesthetic needs of different customers.

How to install polycarbonate embossed and corrugated sheet correctly?

Proper installation of polycarbonate embossed and corrugated sheet requires following these steps:

Before starting the installation, make sure the work area is clean and tidy and the installation location is cleared. Check whether the quantity and size of polycarbonate embossed and corrugated sheet meet the requirements, and prepare the required installation tools and materials.

Make sure to follow safe operating procedures and use appropriate personal protective equipment such as gloves, goggles, etc. during installation.

Use a measuring tool to accurately measure the dimensions of the installation location, and use a marking tool to mark the installation location and boundary lines of the corrugated board on the wall or supporting structure.

Depending on the size of the polycarbonate embossed and corrugated sheet and where it will be installed, prepare the appropriate support structure. Ensure that the supporting structure is solid and strong enough to withstand the weight of the corrugated board and external loads.

Use appropriate tools and cutting methods to cut polycarbonate embossed and corrugated sheet as needed to fit the size and shape of the installation location.

Place the cut corrugated board into the pre-marked mounting location and use suitable fasteners to secure the polycarbonate embossed and corrugated sheet to the supporting structure. Ensure that the number and location of fixings are uniform to ensure the stability and flatness of the corrugated board.

If multiple corrugated panels are required for splicing and installation, ensure there is appropriate overlap and sealing between them. Use sealant or other sealing material to fill the gaps between corrugated sheets to prevent moisture penetration and leakage.

After completing the installation of the polycarbonate embossed and corrugated sheet, perform final tests and adjustments. Check the soundness and flatness of the corrugated board and make sure the installation position is as expected. and make sure the installation position is as expected.