Provide you with the latest enterprise and industry news.

Corrugated polycarbonate sheets have become increasingly popular in both residential and commercial construction due to their durability, lightweight nature, and excellent light transmission. However, one of the most common questions among builders, homeowners, and greenhouse operators is how these sheets perform in cold or snowy climates.

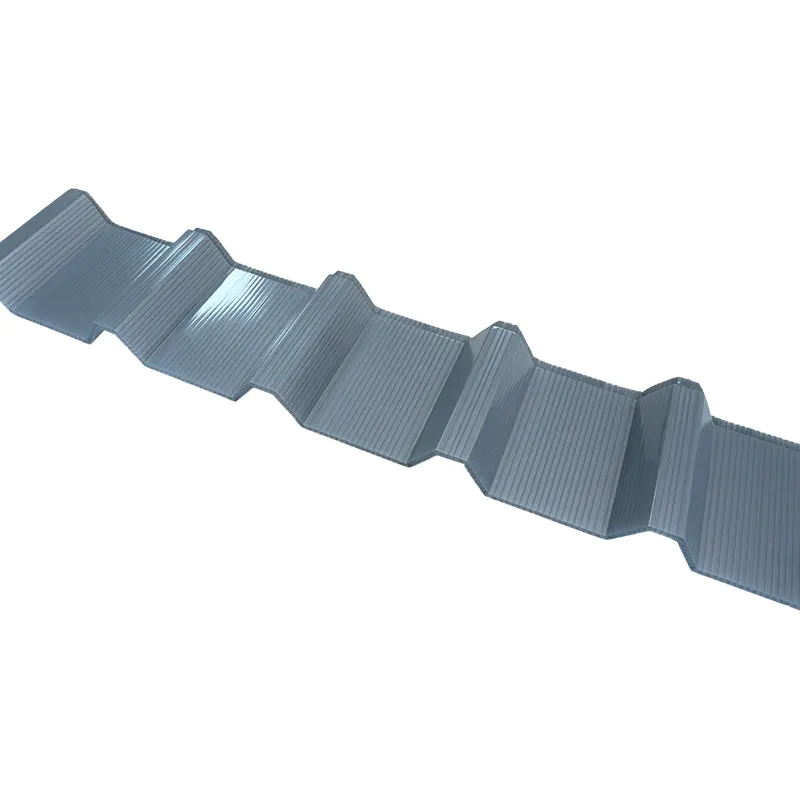

Understanding Corrugated Polycarbonate Sheets

Before diving into their performance in winter conditions, it’s important to understand what corrugated polycarbonate sheets are. Polycarbonate is a type of thermoplastic known for its strength, impact resistance, and transparency. When manufactured in a corrugated pattern, the sheets gain structural rigidity, allowing them to span larger distances and bear weight more effectively.

Some key features of corrugated polycarbonate sheets include:

- Lightweight – Easier to handle and install compared to glass or metal roofing.

- High impact resistance – Can withstand hail, debris, and minor mechanical shocks.

- UV protection – Most sheets are treated with a UV layer to prevent yellowing and degradation from sunlight.

- Thermal performance – Provides insulation and helps maintain temperature stability under varying weather conditions.

These characteristics make corrugated polycarbonate sheets attractive for roofing, skylights, greenhouses, carports, and pergolas.

Challenges of Cold and Snowy Climates

Cold and snowy climates present unique challenges for building materials. Heavy snow accumulation, ice formation, and extreme temperature fluctuations can affect the structural integrity and longevity of roofing and wall systems. Common issues include:

- Snow Load – The weight of accumulated snow can stress roofing materials, causing bending, cracking, or collapse if the material is not designed for heavy loads.

- Thermal Contraction – Low temperatures can cause materials to contract. If the material is rigid or installed without allowance for movement, this can lead to cracking or joint separation.

- Ice Formation – Ice dams and icicles can form along the edges of roofs, increasing the risk of leaks or physical damage.

- Moisture Penetration – Snow that melts and refreezes may seep through unsealed gaps or screw holes, leading to potential water damage.

Given these factors, evaluating how corrugated polycarbonate sheets perform under cold and snowy conditions is essential.

Strength and Structural Performance

One of the primary advantages of corrugated polycarbonate sheets in snowy climates is their structural strength. The corrugated design distributes weight more evenly across the surface, allowing the sheet to support more load than flat sheets of similar thickness. In general, polycarbonate sheets are highly resistant to bending and cracking under moderate snow loads.

However, the performance depends on several factors:

- Sheet thickness – Thicker sheets (e.g., 1.2 mm to 2 mm) can bear heavier snow loads than thinner variants.

- Span distance – The distance between supporting beams or purlins affects how much weight the sheet can support without sagging. Closer spacing increases load-bearing capacity.

- Corrugation profile – Deeper corrugations improve rigidity and allow snow to slide off more easily.

For heavy snowfall areas, it’s recommended to consult local building codes and manufacturer guidelines to ensure the selected sheet thickness and profile can safely handle expected snow loads.

Insulation and Thermal Performance

Cold climates require materials that not only withstand snow and ice but also help regulate indoor temperatures. Corrugated polycarbonate sheets offer moderate thermal insulation, which can be enhanced with multi-wall polycarbonate panels. Multi-wall sheets have air pockets that act as a barrier to heat loss, making them suitable for cold-weather greenhouses or conservatories.

Some benefits of polycarbonate sheets in cold climates include:

- Reduced heat loss – Compared to glass, multi-wall polycarbonate retains more heat indoors.

- Energy efficiency – Maintaining interior warmth reduces heating costs in residential or commercial structures.

- Preventing condensation – Properly installed polycarbonate sheets with ventilation reduce the risk of condensation forming on the underside, which can otherwise freeze and cause damage.

It’s important to note that single-wall polycarbonate sheets provide less insulation and may require additional roofing or insulation layers in very cold regions.

Snow Shedding and Design Considerations

One of the most practical aspects of using corrugated polycarbonate sheets in snowy climates is their ability to shed snow. While the sheets themselves are smooth, steeply pitched roofs are crucial to prevent snow accumulation that could exceed the load capacity.

Key design tips include:

- Roof pitch – A slope of 20–30 degrees or more encourages snow to slide off naturally.

- Sheet overlap – Proper overlapping ensures water runoff and prevents snow melt from seeping between sheets.

- Edge details – Gutter placement and drip edges help manage snowmelt and prevent ice dam formation.

Manufacturers often provide installation guidelines for snowy regions, including recommended slopes and support spacing.

UV Protection and Longevity in Cold Climates

Even in cold climates, UV protection is important. Snow reflects sunlight, which can intensify UV exposure on roofing materials. Most corrugated polycarbonate sheets come with a UV-resistant coating on one side. Correct installation with the UV-protected side facing outward ensures long-term durability and prevents yellowing, brittleness, or cracking.

With proper installation and maintenance, corrugated polycarbonate sheets can last 10–20 years, even in challenging weather conditions.

Maintenance Tips for Snowy Conditions

Regular maintenance is essential to preserve the performance of polycarbonate sheets in cold climates:

- Snow removal – Use a soft-bristled broom to gently remove heavy snow accumulations. Avoid sharp tools that may scratch or puncture the sheet.

- Check fasteners – Screws and bolts can loosen due to thermal contraction and expansion. Regularly inspect and tighten fasteners to maintain a secure roof.

- Inspect for cracks or damage – Cold temperatures can exacerbate minor cracks. Prompt repairs prevent leaks and structural compromise.

- Clean debris and ice – Remove fallen branches, leaves, or ice buildup that may trap moisture and damage the sheets.

Routine maintenance ensures the sheets perform optimally and maintain their structural and thermal benefits.

Limitations and Precautions

While corrugated polycarbonate sheets perform well in cold and snowy climates, there are some limitations:

- Extreme snow loads – In areas with very heavy snowfall, additional structural support may be necessary.

- Abrasion and impact – Ice or debris falling from trees can cause scratches or minor dents, though polycarbonate is generally resilient.

- Temperature sensitivity – Polycarbonate expands and contracts with temperature changes; improper installation without expansion allowance can lead to stress points.

Understanding these limitations helps in planning installations and selecting the right sheet type and thickness.

Conclusion

Corrugated polycarbonate sheets are a highly effective solution for roofing and cladding in cold and snowy climates. Their lightweight design, structural strength, and impact resistance make them suitable for various applications, from residential carports to industrial greenhouses. With proper installation, roof slope, and maintenance, these sheets can withstand heavy snow loads, provide insulation, and maintain their appearance over time.

Key takeaways for using corrugated polycarbonate sheets in snowy regions include:

- Select the correct sheet thickness and corrugation profile based on expected snow loads.

- Ensure proper roof slope to encourage snow shedding.

- Use UV-protected sheets with the coated side facing outward.

- Maintain fasteners, clean snow buildup, and inspect sheets regularly.

- Consider multi-wall polycarbonate for better insulation in cold climates.

By adhering to these guidelines, corrugated polycarbonate sheets can offer durability, safety, and energy efficiency in even the harshest winter conditions. They are not only practical but also a versatile material choice for anyone looking to combine functionality with aesthetic appeal in cold-weather construction projects.