Provide you with the latest enterprise and industry news.

Polycarbonate hollow sheets are widely used in construction and industrial projects because of their strength, light weight, and thermal insulation capabilities. Their transparent or translucent nature allows them to serve effectively in areas that require natural light without sacrificing protection from environmental factors. However, a growing question among architects, engineers, and builders is whether these sheets can also be used for soundproofing applications. Understanding this requires examining their acoustic properties, structural composition, installation methods, and comparative performance with other sound insulation materials.

Understanding the Structure of Polycarbonate Hollow Sheets

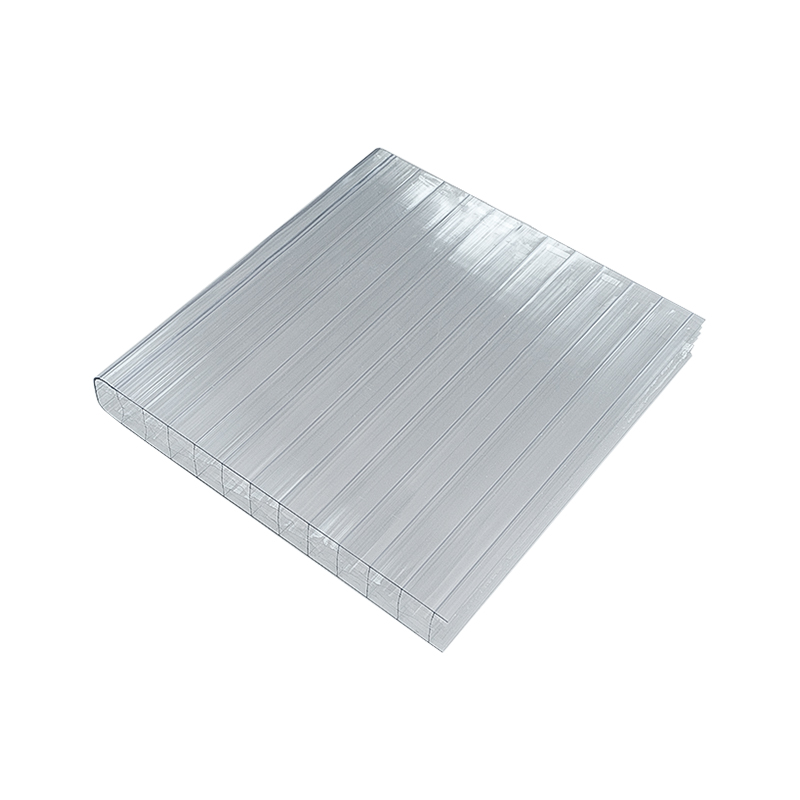

Polycarbonate hollow sheets are made from a thermoplastic polymer known for its durability and impact resistance. Unlike solid sheets, hollow sheets have a multiwall structure that includes air gaps between thin polycarbonate layers. These air gaps serve as insulators, helping reduce heat transfer. Because air is a poor conductor of both heat and sound, this design naturally contributes to a certain degree of sound attenuation. The sheets are available in different thicknesses and configurations such as twin wall, triple wall, and multiwall designs. The thicker the sheet and the greater the number of layers, the better its insulation potential, both thermally and acoustically.

The Role of Soundproofing in Modern Construction

Soundproofing is an important consideration in today’s buildings, especially in urban areas where noise pollution from traffic, machinery, and human activity can affect comfort and productivity. Effective soundproofing materials must either absorb sound waves or block them from passing through. Materials that block sound are typically dense and heavy, such as concrete or laminated glass, while materials that absorb sound tend to be porous, such as acoustic foam or fiberglass panels. Polycarbonate hollow sheets, being lightweight and structured, occupy a unique position between these two categories.

Acoustic Performance of Polycarbonate Hollow Sheets

The soundproofing ability of any material is commonly measured using the Sound Transmission Class (STC) rating. Higher STC ratings indicate better sound insulation performance. Polycarbonate hollow sheets generally have moderate STC ratings, often between 20 and 30, depending on thickness and configuration. This means they can reduce sound transmission to a certain extent but are not entirely effective in blocking high levels of noise.

In practical terms, polycarbonate hollow sheets can provide a noticeable reduction in moderate ambient noise, such as conversations or wind, but they are less effective against low frequency sounds or loud industrial noises. For example, using multiwall sheets of greater thickness, such as 10 millimeters or more, can slightly improve the acoustic barrier. Yet, even with this improvement, they remain less effective than materials specifically engineered for sound insulation.

Factors That Influence Acoustic Efficiency

Several factors determine how well polycarbonate hollow sheets perform in soundproofing applications.

1. Thickness and Structure

Thicker sheets with more internal chambers offer better sound reduction. A triple wall sheet will generally perform better than a twin wall one because the extra air gap increases the distance sound must travel, thereby reducing its energy.

2. Installation Method

Gaps and joints between sheets can become weak points for sound transmission. To enhance sound reduction, sheets must be properly sealed using silicone or rubber gaskets to prevent air leaks. Incorrect installation can significantly reduce the soundproofing performance even if the sheet itself is of good quality.

3. Framing and Mounting System

The frame that holds the sheets plays an important role in acoustic control. Metal frames, for instance, can transmit vibrations easily, reducing the overall effectiveness. Using damping materials or flexible joints can help isolate vibrations and improve performance.

4. Surface Treatments and Coatings

While most coatings on polycarbonate sheets are designed for UV protection or anti-condensation, some specialized acoustic laminations can slightly enhance sound insulation. However, these treatments are uncommon and may not be available for standard building projects.

Comparing Polycarbonate Hollow Sheets with Other Soundproofing Materials

To understand whether polycarbonate hollow sheets are suitable for soundproofing, it helps to compare them with conventional acoustic materials.

1. Versus Glass

Glass, especially laminated glass, is denser and heavier than polycarbonate. This makes glass more effective in blocking sound. However, glass is brittle and heavier, which increases installation difficulty and cost. Polycarbonate hollow sheets are easier to install, lighter, and safer, though they provide less sound reduction.

2. Versus Acrylic Sheets

Acrylic sheets are similar in appearance to polycarbonate but have slightly higher density. This allows acrylic to perform somewhat better acoustically. Yet, acrylic lacks the impact resistance and flexibility that polycarbonate provides.

3. Versus Acoustic Panels and Foam

Acoustic foam and panels are specifically designed to absorb sound, not necessarily to block it. These materials are highly effective indoors but unsuitable for outdoor applications where weather resistance is important. Polycarbonate hollow sheets, on the other hand, can function well outdoors while providing modest noise reduction.

4. Versus Solid Polycarbonate Sheets

Solid polycarbonate sheets are denser and therefore better at blocking sound than hollow ones. However, they also cost more and weigh more. For situations where both transparency and moderate sound control are required, solid sheets may be preferable, but hollow sheets remain a more cost effective and lighter option.

Practical Applications of Polycarbonate Hollow Sheets for Sound Reduction

Although polycarbonate hollow sheets are not specialized acoustic barriers, they can still contribute to sound control in specific contexts.

1. Greenhouses and Agricultural Buildings

In greenhouses, where noise insulation is not a top priority, hollow sheets help reduce wind noise and vibrations, making the environment calmer without sacrificing light transmission.

2. Industrial Sheds and Warehouses

In factories or storage facilities where light and temperature control are more critical than full soundproofing, polycarbonate hollow sheets can reduce echo and dampen environmental noise slightly.

3. Parking Shelters and Carports

Hollow sheets used in carports can help muffle rain noise and provide partial isolation from traffic sounds.

4. Sports Facilities and Sound Barriers

Some outdoor sports facilities use polycarbonate hollow sheets as part of their barriers to limit noise spread while maintaining visibility. However, these are typically used alongside other materials to improve effectiveness.

5. Office Partitions and Skylights

In modern architectural designs, hollow polycarbonate sheets can be used as partitions that provide visual separation and moderate noise control in office spaces, though not complete soundproofing.

Enhancing the Soundproofing Potential

There are practical ways to improve the acoustic performance of polycarbonate hollow sheets.

1. Double Layer Systems

Using two layers of sheets separated by an air gap can enhance sound insulation significantly. The additional air space acts as a secondary barrier that further reduces sound transmission.

2. Combining with Other Materials

Pairing polycarbonate hollow sheets with sound absorbing materials such as mineral wool or acoustic foam behind the panels can achieve a balanced solution that offers both light transmission and noise control.

3. Sealing and Framing Improvements

Ensuring that all joints are airtight prevents sound leakage. Frames can be lined with rubber seals or vibration absorbing materials to minimize sound transfer through the structure.

4. Using Acoustic Films or Laminations

Although not common, some projects may apply thin acoustic films to the surface of the polycarbonate to increase density and improve sound blocking properties.

Limitations of Polycarbonate Hollow Sheets for Soundproofing

While polycarbonate hollow sheets provide a degree of sound reduction, their limitations should be clearly understood. Their lightweight design makes them less effective in blocking low frequency or high intensity noise. They are not an ideal choice where full sound isolation is necessary, such as recording studios, conference rooms, or residential buildings near highways. In such environments, specialized soundproofing systems with dense materials are required.

Additionally, improper installation can drastically reduce performance. Even small gaps can allow sound to pass through, negating any benefits the material provides. For this reason, polycarbonate hollow sheets are best considered a secondary or supportive component in a larger sound control strategy rather than the primary barrier.

Balancing Soundproofing with Other Benefits

Despite their limited soundproofing capabilities, polycarbonate hollow sheets offer several other benefits that make them appealing in architectural and industrial applications. They provide excellent light diffusion, energy efficiency through thermal insulation, and impact resistance. They are also lightweight, easy to install, and resistant to environmental factors such as moisture and ultraviolet radiation. In many designs, these properties outweigh the need for complete soundproofing.

When evaluating materials for a project, it is important to balance acoustic performance with other requirements such as safety, durability, maintenance, and cost. Polycarbonate hollow sheets may not be the top performer in sound insulation, but they can still contribute positively when used in combination with complementary materials.

Conclusion

Polycarbonate hollow sheets offer limited but useful soundproofing properties. Their hollow multiwall design provides some sound attenuation by trapping air between layers, reducing moderate noise levels. However, they are not a substitute for dedicated soundproofing materials where complete noise control is essential. Their primary strengths lie in their durability, light transmission, and thermal insulation rather than acoustic isolation.

For applications such as greenhouses, skylights, industrial sheds, or carports, polycarbonate hollow sheets can serve as a practical choice that balances lightness, weather resistance, and moderate sound reduction. For projects that demand higher levels of noise control, these sheets can be combined with other sound absorbing or blocking materials to achieve better results.

In conclusion, polycarbonate hollow sheets are suitable for environments that require moderate sound dampening alongside other structural and aesthetic benefits. They are not ideal as a stand alone solution for soundproofing but can play a supportive role in achieving overall acoustic comfort when used thoughtfully within a broader design approach.