Provide you with the latest enterprise and industry news.

Polycarbonate hollow sheets, also known as multiwall polycarbonate panels, are widely used in construction, agriculture, and industrial applications due to their durability, light transmission, and thermal insulation properties. This article explores their benefits, applications, installation tips, and key considerations to help you make an informed decision.

What Are Polycarbonate Hollow Sheets?

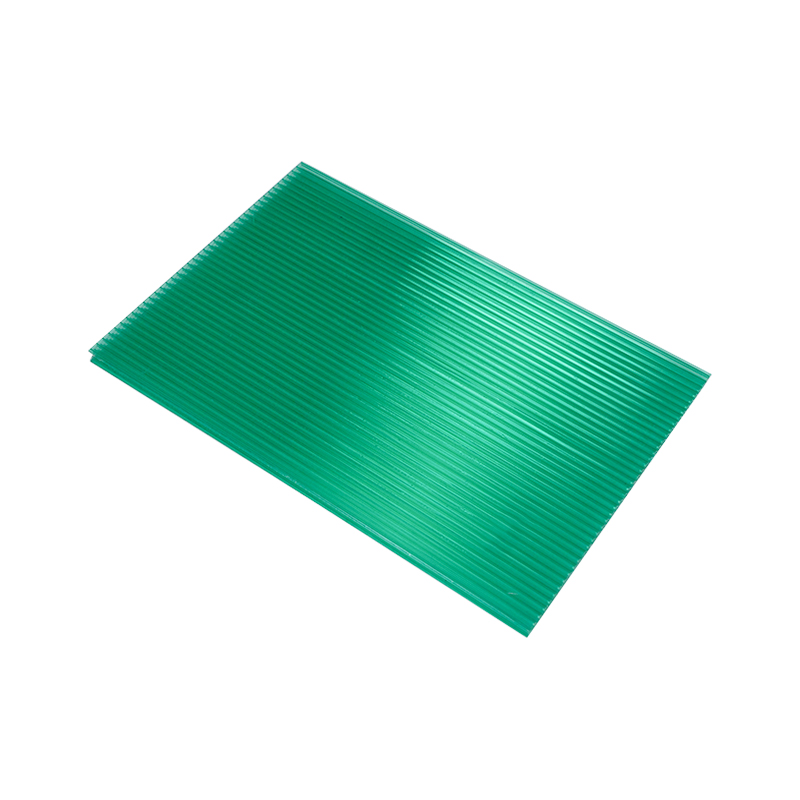

Polycarbonate hollow sheets are lightweight, impact-resistant panels with a hollow, multi-chambered structure. These chambers provide excellent insulation while allowing natural light to pass through. Unlike solid polycarbonate sheets, the hollow design reduces weight without sacrificing strength.

Key Features:

- High impact resistance

- UV protection

- Lightweight yet durable

- Excellent thermal insulation

- Good light transmission (up to 80%)

- Fire-resistant properties

Applications of Polycarbonate Hollow Sheets

Due to their versatility, these sheets are used in various industries:

| Application | Benefits |

| Roofing & Skylights | Provides natural light, reduces heat transfer, and withstands harsh weather. |

| Greenhouses | Optimizes sunlight diffusion, maintains consistent temperatures, and resists hail damage. |

| Partitions & Canopies | Lightweight, easy to install, and offers sound insulation. |

| Industrial Sheds | Durable, fire-resistant, and reduces energy costs. |

| Noise Barriers | Effective sound dampening for highways and urban areas. |

Advantages Over Other Materials

Polycarbonate hollow sheets outperform traditional materials like glass, acrylic, and PVC in several ways:

- Durability – Up to 200 times stronger than glass, making them resistant to breakage.

- Lightweight – Easier to handle and install compared to glass or metal sheets.

- Thermal Efficiency – The hollow chambers reduce heat transfer, lowering energy costs.

- UV Protection – Most sheets come with a UV-resistant coating to prevent yellowing and degradation.

- Design Flexibility – Available in various thicknesses (4mm to 25mm) and colors.

Installation Tips for Polycarbonate Hollow Sheets

Proper installation ensures longevity and performance. Follow these guidelines:

1. Use the Right Tools & Materials

- Fasteners: Use rubber washers and self-drilling screws to prevent leaks.

- Sealants: Apply compatible silicone sealant on edges to prevent moisture ingress.

- Cutting: Use a fine-toothed saw or circular blade for clean cuts.

2. Allow for Thermal Expansion

Polycarbonate expands and contracts with temperature changes. Leave a 3-5mm gap between panels and use expansion-capable profiles.

3. Correct Orientation

Install the sheets with the UV-protected side facing outward to maximize lifespan.

4. Proper Support & Spacing

Depending on thickness, support spacing should be:

| Sheet Thickness (mm) | Maximum Support Spacing (cm) |

| 4mm – 6mm | 50 – 70 cm |

| 8mm – 10mm | 80 – 100 cm |

| 16mm – 25mm | 120 – 150 cm |

Maintenance & Care

Though polycarbonate hollow sheets are low-maintenance, follow these steps to ensure longevity:

- Cleaning: Use mild soap and water; avoid abrasive cleaners.

- Inspection: Check for cracks or sealant deterioration annually.

- Drainage: Ensure channels are clear to prevent water pooling.

Common Mistakes to Avoid

- Ignoring UV Coating Direction – Installing sheets upside down reduces UV protection.

- Over-tightening Screws – Can cause stress cracks.

- Poor Edge Sealing – Leads to moisture buildup and algae growth.

Conclusion

Polycarbonate hollow sheets are an excellent choice for projects requiring durability, insulation, and natural light transmission. Whether for roofing, greenhouses, or industrial use, their benefits make them a cost-effective and long-lasting solution. By following proper installation and maintenance practices, you can maximize their performance for years to come.

Would you like additional details on specific applications or comparisons with other materials? Let us know in the comments!