Provide you with the latest enterprise and industry news.

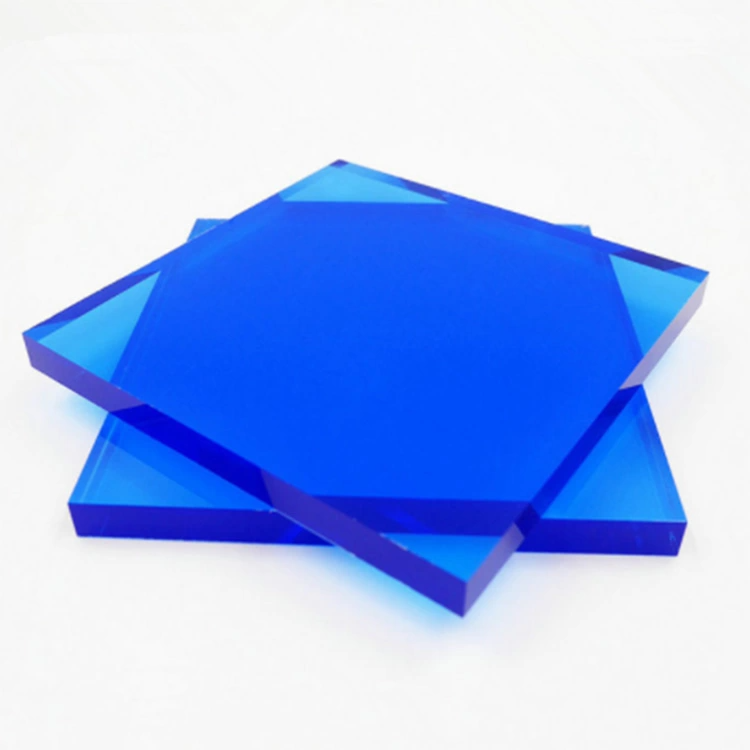

In the ever-evolving world of architectural design, the quest for materials that marry form and function is perpetual. Architects and designers constantly seek solutions that are not only structurally sound and durable but also offer aesthetic flexibility and modern appeal. While glass has long been the traditional choice for transparent and translucent applications, a powerful alternative has cemented its place in the built environment: acrylic sheet material.

Known commercially by names like Plexiglas, Lucite, and Perspex, acrylic is a synthetic polymer that has transcended its humble origins to become a cornerstone of innovative design.

What Exactly is Acrylic? Beyond the Basics

At its core, acrylic is a thermoplastic known as polymethyl methacrylate (PMMA). First developed in the 1920s and widely commercialized in the 1930s, it was initially used for canopies, windshields, and turrets in World War II aircraft due to its exceptional clarity and shatter-resistance. This legacy of strength and transparency directly informs its architectural use today.

Unlike glass, which is an amorphous solid, acrylic is a plastic. However, to dismiss it as “just plastic” would be a significant underestimation of its capabilities. Modern manufacturing processes, including cell casting and continuous casting, produce sheets of incredibly high quality, optical clarity, and consistency, making them ideal for demanding architectural applications.

Key Properties: Why Architects Choose Acrylic

The widespread adoption of acrylic in architecture is driven by a compelling set of physical and optical properties.

1. Exceptional Impact Resistance and Safety

This is arguably acrylic’s most significant advantage over glass. Acrylic plastic sheeting is up to 17 times more impact-resistant than standard glass of the same thickness. This inherent toughness makes it highly resistant to breakage from impact, weather, and vandalism. When it does break under extreme force, it fractures into large, dull-edged pieces rather than sharp, dangerous shards. This characteristic as a shatter-resistant glazing alternative makes it an excellent choice for areas where safety is a paramount concern: schools, athletic facilities, public transit shelters, and security barriers.

2. Superior Lightweight Properties

Acrylic weighs approximately half as much as glass. A ½-inch thick acrylic sheet weighs less than a ¼-inch thick glass pane. This drastic reduction in weight simplifies every stage of a project:

Transportation: Lower shipping costs.

Handling: Easier and safer for installers to maneuver, reducing the risk of injury and installation error.

Structural Support: Requires less robust and therefore less expensive supporting frameworks. This is a critical factor in retrofitting older buildings or designing intricate facades where minimizing dead load is essential.

3. Outstanding Optical Clarity and Light Transmission

High-quality cast acrylic sheets offer 92% light transmission, which is actually higher than glass (typically 80-90%). This superior clarity means views are brighter and clearer. Furthermore, acrylic can be manufactured to be incredibly optically perfect, eliminating distortions—a key feature for applications like museum display cases, aquarium windows, and high-end architectural signage.

4. Unmatched Versatility in Form and Function

This is where acrylic truly shines. Its thermoplastic nature means it can be heated and formed into virtually any shape—simple curves, complex double-curvatures, and sharp angles—all while maintaining its strength. This thermoformable building material capability allows architects to create dynamic, fluid forms that would be prohibitively expensive or impossible with glass.

Furthermore, acrylic is available in a vast array of types:

Colors: Every conceivable hue, from vibrant tones to subtle tints.

Textures: Opaque, transparent, translucent, and a range of finishes like matte, glossy, and patterned (e.g., fluted acrylic panels).

Specialty Types: Light-diffusing sheets, mirrored acrylic, anti-reflective, UV-filtering, and bullet-resistant grades.

5. Enhanced Weathering and UV Resistance

While early plastics were prone to yellowing and degradation from sunlight, modern acrylic sheets are formulated with advanced additives. High-quality extruded or cast acrylic features excellent weatherability and inherent resistance to UV light, ensuring long-term color stability and clarity. This makes it ideal for outdoor applications like exterior cladding, skylights, and canopies.

6. Ease of Fabrication and Modification

Acrylic is a dream material for fabricators. It can be cut, drilled, routed, and polished with standard woodworking and metalworking tools. This ease of fabrication allows for high levels of customization and intricate detailing on-site, facilitating complex designs and quicker turnaround times compared to glass.

Architectural Applications: From Concept to Reality

The properties of acrylic translate into a diverse range of real-world applications across residential, commercial, and public architecture.

1. Modern Skylights and Roof Domes

The combination of light weight, impact resistance, and superior light transmission makes acrylic a superior material for skylights and roof domes. Its ability to be thermally formed into domed shapes allows for innovative roof designs that flood interior spaces with natural light, reducing reliance on artificial lighting and lowering energy costs. Its safety profile is a major advantage in overhead glazing.

2. Dynamic Interior Partitions and Walls

Decorative acrylic partitions have become a staple in modern office and commercial design. They can define spaces without sacrificing the open, airy feel that contemporary layouts demand. Frosted, tinted, or fluted acrylic panels provide visual privacy while still transmitting light. Their lightweight nature makes reconfiguring office layouts a simpler task.

3. Protective and Decorative Barriers

In the post-pandemic era, the need for protective barriers has increased. Acrylic sneeze guards and partitions offer clear protection without creating a claustrophobic or visually heavy environment. Beyond hygiene, acrylic is used for balcony railings, mezzanine barriers, and museum rope line barriers, offering safety without obstructing views.

4. Signage and Branding Elements

From back-lit channel letters to sleek interior signage, acrylic is the industry standard. Its ability to be precision-cut, edge-lit, and beautifully finished allows brands to create a high-impact, professional presence. Custom acrylic fabrication enables unique, branded architectural elements like reception desks and logo walls.

5. Artistic Installations and Feature Walls

The aesthetic potential of acrylic is limitless. Designers use layered, colored, and lit acrylic sheets to create stunning artistic installations and feature walls. The material can mimic the look of etched glass, natural stone (in translucent form), or ice, providing a cost-effective way to achieve a high-end, custom look.

6. Exterior Cladding and Façades

Lightweight cladding solutions are a growing trend, and acrylic panels are at the forefront. Fluted or textured acrylic panels can create rhythm and depth on a building’s exterior. Their light weight reduces the load on the building’s structure, and their impact resistance ensures longevity. Tinted panels can also contribute to solar heat gain management.

7. Retail Display and Museum Showcases

The unparalleled optical clarity and ability to be formed into seamless, curved displays make acrylic the material of choice for high-end retail and museums. It protects priceless artifacts and luxury goods from dust and UV damage while presenting them with minimal visual obstruction.

Acrylic vs. Polycarbonate: Choosing the Right Polymer

A common question arises when considering plastic glazing: acrylic or polycarbonate? While both are thermoplastics, they have distinct differences.

Strength: Polycarbonate is the undisputed champion of impact resistance, being about 30 times stronger than acrylic. It is the go-to for true security glazing and applications requiring extreme vandal resistance.

Clarity & Weathering: Acrylic is the winner here. It offers better optical clarity and is much more resistant to yellowing and scratching over time. Polycarbonate almost always requires a scratch-resistant coating for exterior use, while acrylic’s surface is inherently harder.

Cost: Acrylic is generally more cost-effective than polycarbonate.

The simple rule of thumb: Choose polycarbonate if your primary concern is extreme impact resistance (e.g., prison windows, sports arenas). Choose acrylic for applications where optical clarity, weatherability, and a balance of strength and cost are key (e.g., skylights, windows, aesthetic partitions).

Sustainability and Environmental Considerations

The conversation about any synthetic material must include its environmental footprint. Acrylic is not biodegradable, but it is 100% recyclable (Thermoplastic Code 7). The industry is making strides in creating closed-loop recycling processes for manufacturing waste and end-of-life products.

Furthermore, its long service life—often decades—means it is not a disposable material. Its contribution to energy efficiency through daylighting and its role in lightweight construction (reducing the embodied energy of supporting structures) add to its sustainable credentials. When specifying acrylic, look for suppliers who incorporate recycled content and have clear take-back or recycling programs.

Installation and Maintenance Best Practices

To ensure the longevity and beauty of an acrylic installation, proper handling is crucial.

Protective Film: Acrylic sheets come with a protective masking film. Leave this on throughout the fabrication and installation process to prevent scratches, and only remove it once the installation is complete and the site is clean.

Cleaning: Use a soft, non-abrasive cloth (microfiber is ideal) and a mild soap solution. Avoid harsh chemicals, ammonia-based cleaners (like Windex), and abrasive cloths, as they can scratch the surface.

Thermal Expansion: Acrylic expands and contracts with temperature changes more than glass. Installations must account for this movement by using appropriate mounting systems with rubber gaskets and oversized drill holes to prevent stress cracking.

Static Electricity: Acrylic can attract dust due to static. Using an anti-static cleaner can help mitigate this in interior applications.

The Future is Clear

Acrylic sheet material has firmly established itself as an indispensable tool in the architect’s kit. It is no longer merely a substitute for glass but a high-performance material in its own right, enabling designs that are stronger, lighter, more creative, and more efficient.

As manufacturing technologies advance, we can expect to see even more innovative acrylic products—smart panels with integrated LEDs, dynamic privacy glass alternatives, and ever-more sustainable formulations. For architects and designers committed to creating strong, versatile, and stylish spaces, acrylic offers a world of possibility, proving that the most visionary designs are often built on a foundation of clear, brilliant innovation.