Provide you with the latest enterprise and industry news.

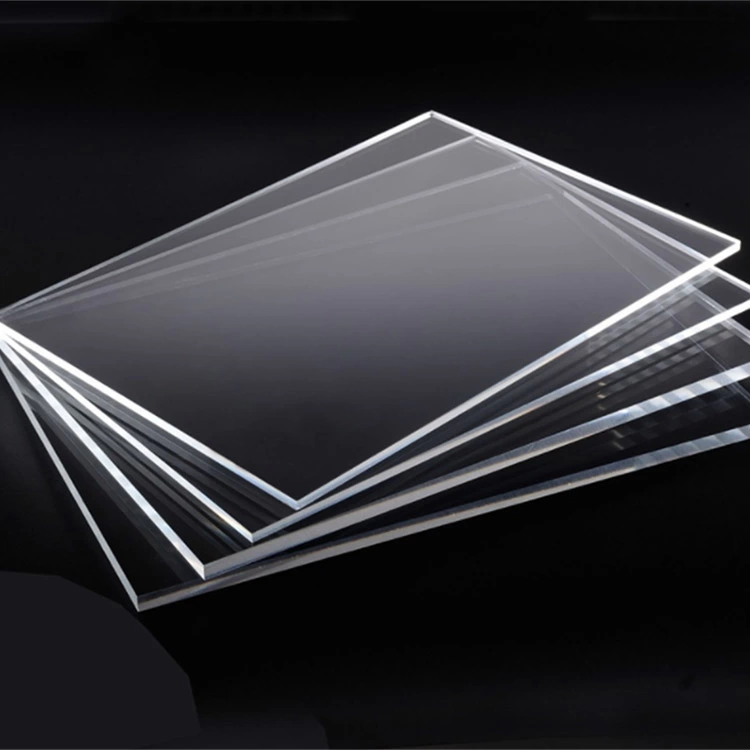

Acrylic sheet, also known as plexiglass or acrylic glass, are versatile plastic materials used in countless applications. This comprehensive guide covers everything you need to know about acrylic sheets, from their properties and benefits to practical uses and selection tips.

What is an Acrylic Sheet?

Acrylic sheets are transparent thermoplastic panels made from polymethyl methacrylate (PMMA). They serve as a shatter-resistant alternative to glass with better light transmission and weather resistance than many other plastics.

Key Properties of Acrylic Sheets

| Property | Value | Advantage |

| Light Transmission | 92% | Clearer than glass |

| Impact Resistance | 10-20x glass | Less likely to break |

| Weight | 50% lighter than glass | Easier to handle |

| UV Resistance | Excellent | Won't yellow easily |

| Temperature Range | -40°F to 180°F | Wide usability |

Popular Uses of Acrylic Sheets

Acrylic's versatility makes it suitable for numerous applications:

Home and Interior Applications

- Shower enclosures and tub liners

- Furniture tops and protective surfaces

- Room dividers and privacy screens

- Picture frames and display cases

- Skylights and light fixtures

Commercial and Industrial Uses

- Retail displays and signage

- Greenhouse panels

- Machine guards and safety barriers

- Aquariums and fish tanks

- Medical and laboratory equipment

Types of Acrylic Sheets

| Type | Description | Best For |

| Extruded Acrylic | Continuous production process, uniform thickness | General purpose applications |

| Cast Acrylic | Cell-cast process, superior optical quality | Precision applications, machining |

| Colored Acrylic | Pigmented sheets in various colors | Decorative purposes, signage |

| Mirrored Acrylic | Reflective surface on one side | Decorative mirrors, displays |

| Anti-Glare Acrylic | Surface treatment reduces reflections | Display cases, picture framing |

How to Choose the Right Acrylic Sheet Thickness

Selecting the proper thickness is crucial for your project's success:

| Thickness (inches) | Applications | Notes |

|---|---|---|

| 0.06" - 0.118" (1.5mm - 3mm) | Picture frames, small displays, crafts | Lightweight but less durable |

| 0.177" - 0.236" (4.5mm - 6mm) | Shelves, signage, small aquariums | Good balance of strength and weight |

| 0.315" - 0.472" (8mm - 12mm) | Large displays, partitions, furniture | Substantial weight but very durable |

| 0.551" and up (14mm+) | Structural applications, heavy-duty uses | Professional/industrial applications |

Cutting and Fabricating Acrylic Sheets

Working with acrylic requires proper techniques to avoid cracking or melting:

Basic Cutting Methods

- Scoring and snapping: For thin sheets (up to 1/8") - use a scoring tool and straight edge

- Circular saw: Use fine-toothed blade (80+ teeth) at moderate speed

- Laser cutting: Precise method for complex shapes

- CNC routing: For production work and precise cuts

Tips for Drilling Acrylic

- Use sharp drill bits designed for plastics

- Drill at slow speed (500-1000 RPM)

- Apply light, consistent pressure

- Use backing board to prevent chipping

- Clear chips frequently to prevent melting

Acrylic Sheet vs Polycarbonate vs Glass

| Feature | Acrylic | Polycarbonate | Glass |

| Clarity | Excellent (92%) | Good (88%) | Excellent (90-92%) |

| Impact Resistance | Good (10-20x glass) | Excellent (250x glass) | Poor |

| Scratch Resistance | Good | Poor | Excellent |

| UV Resistance | Excellent | Good (with coating) | Excellent |

| Weight | Light (1.19 g/cm³) | Light (1.2 g/cm³) | Heavy (2.5 g/cm³) |

| Cost | Moderate | High | Low to High |

Maintenance and Cleaning Tips

Proper care extends the life of acrylic sheets:

- Use mild soap and water for routine cleaning

- Always use a soft, lint-free cloth (microfiber recommended)

- Wipe in straight lines, not circles, to minimize visible scratches

- Avoid ammonia-based cleaners (like window cleaner)

- For stubborn stains, use isopropyl alcohol diluted with water

- Remove stickers with plastic razor blades to prevent scratching

Common Mistakes to Avoid with Acrylic Sheets

- Using paper towels for cleaning: Can cause fine scratches

- Improper storage: Store flat and horizontal to prevent warping

- Over-tightening fasteners: Can cause stress cracks

- Cutting without proper support: Leads to chipping

- Exposing to harsh chemicals: Can cause crazing or cracking

Where to Buy Acrylic Sheets

Acrylic sheets are available through various channels:

- Local plastic suppliers: Offer expert advice and may provide cutting services

- Home improvement stores: Typically carry small sizes for DIY projects

- Online retailers: Wide selection but shipping costs can be high for large sheets

- Industrial suppliers: Best for bulk purchases and specialized types

Cost Considerations for Acrylic Sheets

Prices vary based on several factors:

| Factor | Price Impact |

| Thickness | Thicker sheets cost significantly more |

| Size | Larger sheets have higher absolute cost but lower cost per square foot |

| Type | Cast acrylic typically costs 20-40% more than extruded |

| Color/Specialty | Colored, mirrored, or textured sheets command premium prices |

| Quantity | Volume discounts typically available for large orders |

Environmental Considerations

Acrylic has both advantages and disadvantages from an environmental perspective:

- Long lifespan: Durable material reduces need for replacement

- Recyclability: Can be recycled but facilities may be limited

- Production impact: Manufacturing requires petroleum products

- Biodegradability: Does not biodegrade in landfills

- Energy efficiency: Light weight reduces transportation energy

Frequently Asked Questions About Acrylic Sheets

How long do acrylic sheets last?

With proper care, acrylic sheets can last 10-20 years outdoors and even longer indoors. UV-resistant grades maintain clarity longer when exposed to sunlight.

Can acrylic sheets be bent or shaped?

Yes, acrylic becomes pliable when heated to 300-350°F (150-180°C) and can be formed into various shapes. This requires proper equipment and technique to avoid bubbles or stress marks.

Is acrylic sheet fire resistant?

Standard acrylic is flammable (Class B rating). Fire-retardant grades are available but more expensive. Never use standard acrylic where building codes require fire-rated materials.

Can you paint acrylic sheets?

Yes, but proper surface preparation is essential. Use paints specifically formulated for plastics, and consider the side that won't be visible for best results.

How do you remove scratches from acrylic?

Light scratches can be polished out with plastic polish or a mild abrasive like toothpaste. Deep scratches may require professional polishing or wet sanding.

Conclusion

Acrylic sheets offer an exceptional combination of clarity, durability, and versatility that makes them suitable for countless applications. By understanding the different types, thickness options, and proper handling techniques, you can select the right acrylic sheet for your project and ensure it performs well for years to come. Whether you're creating displays, protective barriers, or decorative elements, acrylic provides a practical alternative to glass with numerous benefits.